Innovative Design

Alltherm's custom refractory system primarily features ceramic fiber insulation panel modules. Light-weight and easy to install, we offer the best modules on the market that set the industry standard in energy efficiency and cost reduction.

Our innovative design allows a rebuild or retrofit of any preexisting design to allow a complete relining and willfully maintain any side wall, door, roof, lids, launder systems, or covers. With our unique ceramic fiber module design we can create larger, longer lasting seals inside your furnace, often surpassing the industry standard without repairs or maintenance.

Operating Furnace Doors

For many years, furnace operators looked upon furnace doors and necessary evils in the operation of their furnaces. Furnace doors were improperly sealed, ill-fitted, and short lived. All of which led to decreased productivity due to the operating inefficiencies and increased furnace downtime.

Alltherm designs and manufactures doors that alleviate these problems and become a viable component of the design and operation of the furnace. The ceramic fiber modules system used as a furnace roof is also an innovative concept currently in use by several of our customer. As of September 1991, a fiber roof was installed for a die caster, the first of its kind in the country.

The Alltherm ceramic door systems are superior due their design, engineering, and installation. Each door is specifically design to a customer specific requirement and needs. Compared to hard refractory door, ceramic fiber doors are half the weight. This benefit reduces the stress and strain on the equipment used to close the doors. The one-piece modular design of the door system allows for quick, easy, and inexpensive replacement of damaged or worn ceramic fiber blankets. Simplified door closure systems efficiently seal the furnace, increasing the efficiency of the furnace. These improvements result in reduced fuel consumption, reduced down-time, improvement in furnace efficiency, less maintenance, and improved longevity for our customers.

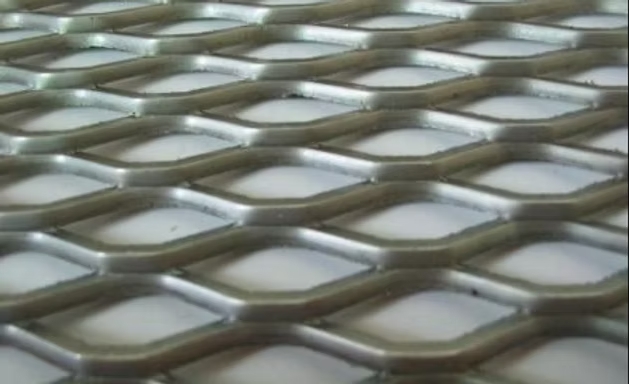

Fiber Shrinkage

Ceramic fiber shrinkage is a major problem. Our state-of-the-art ceramic fiber modular system design and production techniques has established Alltherm as a leader in the manufacturing of ceramic fiber products. We have designed a fiber compression machine that allows for a density of 12 ½ pounds of compression per square foot. Our nearest competitor hand fold and compresses the fiber to approximately 11 -11 ½ pounds per cubic foot. The density increase is a major component of our products superiority to our competitors.