Custom Furnace Fabrication with Ceramic Fiber Modules

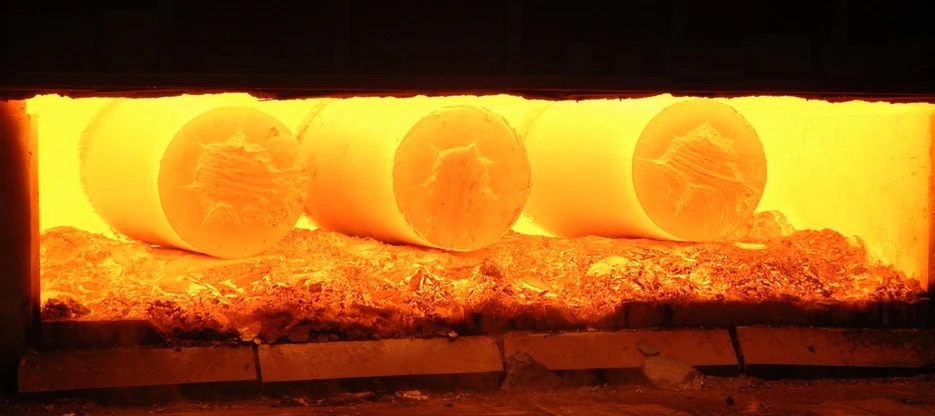

Alltherm leads the refractory industry in custom furnace fabrication using the cutting-edge design of our ceramic fiber modules. With use of our "Positive Plus R-1" stainless steel anchoring system, we are able to produce energy saving, longer lasting ceramic fiber modules. These unique models are light-weight, and are able to create a fuller, more efficient seal that has been known to save up to 20% of energy cost when compared to traditional furnace brick or castable linings. Not only are they cheaper to maintain and easy to install, but also much more effective at keeping your furnace at it targeted temperature.

Alltherm also invented a new way of manufacturing the ceramic fiber modules that insulate a furnace. Prior to Alltherm’s “Positive Plus-R1” ceramic fiber anchoring system, fiber modules were small and notorious for heat loss. Alltherm invented a special fabrication “rack” that allows for Alltherm to build modules in one continuous piece. This innovative construction approach dramatically extends the life of the inside of a furnace.

To find out more about our ceramic fiber modules please click the button below

Custom Fabrication of Furnaces

This fabrication process can be applied to a variety of different furnace designs. To be specific here are some furnace design we have incorporated our custom fabrication process into:

- Melting furnaces

- Holding furnaces

- Forge furnaces

- Heat-treat furnaces

- Molten metal transfer launders

- Crucible furnaces

- Dry hearth furnaces

- Transfer ladles

- Other furnace types

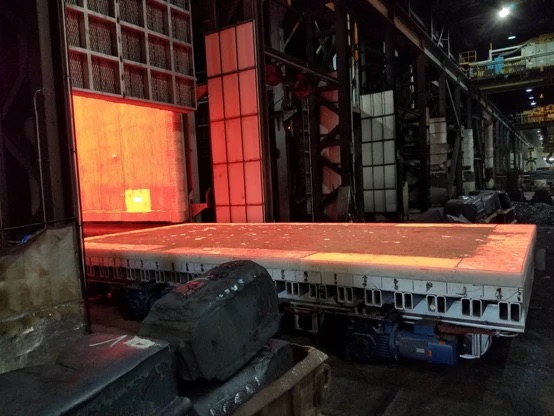

Forge Furnace

Take a look at a forging furnace we had just recently completed for one of our clients.

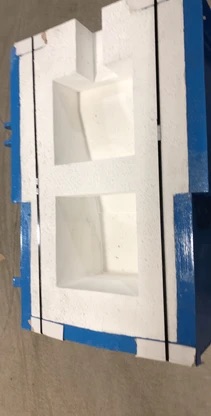

Precast Shapes & Custom Pours

Alltherm also manufactures and offers a variety of precast shapes and casting services. These precast shapes are used as insulators into our custom fabrication process.

Holding Furnaces

We can manufacture a new holding furnace or use your existing holder. In our shop saves you money, in your shop saves you time! We've done hundreds of holding furnaces, working off of different designs to provide a unique, innovative furnace. We know the tricks of the trade and perform the highest quality of refractory work in the market- at very competitive prices.

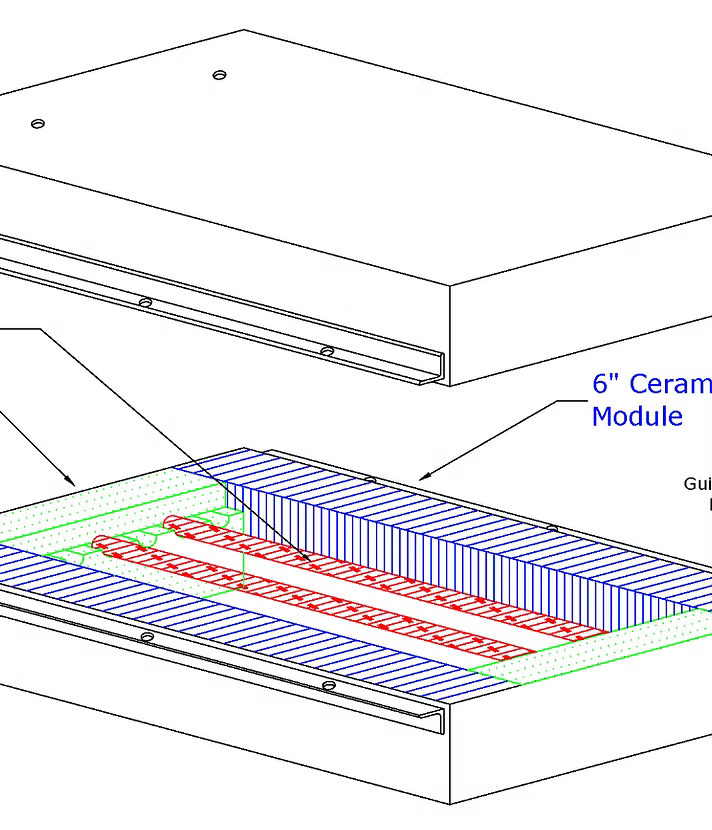

Electric Holding Cover

Alltherm specializes in manufacturing our electric element lid covers or retrofit your existing covers! Our innovative, split lid cover will be designed for maximum energy usage and a longer product life cycle.

Take a look below to check out our design:

For more information on our elements, or on our Split Lid design click on the button below:

Alltherm has over 35 years of experience in casting and performing custom pours of hard refractory materials. In our years of service we have excelled in pouring furnaces of these types:

- Stack melters

- Reverbs or central melters

- Dry hearths

- Barrel

- Holding

- Other varieties

Contact us or one of our sales representatives to find out how we can service your facility

•••

Serving Customers Locally & Nationwide